In today’s volatile energy landscape, manufacturers are being challenged to shift their perspective from viewing energy as a fixed cost to treating it as a controllable, strategic asset. This shift is at the heart of energy optimization, through blending data, technology, and operational insights to drive smarter, cleaner, and more resilient industrial performance.

Energy optimization begins with visibility. Through smart metering, sub-metering, and real-time analytics, manufacturers can pinpoint exactly where energy is being consumed and more importantly where it’s being wasted. These insights allow for targeted interventions, such as adjusting HVAC systems, fine-tuning production schedules, and identifying inefficient equipment. The result is not just lower energy bills, but improved operational efficiency and reduced environmental impact.

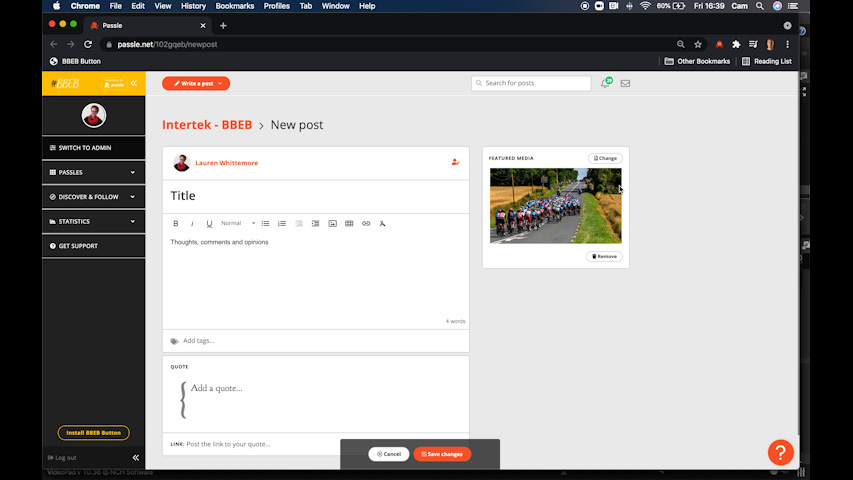

Optimization doesn’t just stop on the factory floor. It extends into procurement strategies, demand forecasting, and even employee engagement. Manufacturers are increasingly adopting energy dashboards and digital twins to simulate energy scenarios and make informed decisions. By integrating energy data into broader business intelligence platforms, companies can align energy use with production goals, sustainability targets, and financial performance.

This approach also supports ESG commitments. Reducing energy intensity and carbon emissions helps manufacturers meet regulatory requirements, attract investment, and build trust with stakeholders. It’s a proactive way to demonstrate environmental responsibility while enhancing competitiveness.

Energy optimization exemplifies the BBEB philosophy: building back ever better by embedding sustainability into the core of strategy. It’s not just about reacting to rising costs, it’s about designing systems that are agile, intelligent, and future-ready.

In a world where energy is both a risk and an opportunity, manufacturers that take control of their energy use are leading the way toward a more sustainable and resilient future.

“Get to net zero” is clear; the route isn’t.

https://www.themanufacturer.com/articles/energy-optimisation-from-cost-to-control/

unknownx500

unknownx500

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2026-01-12-14-56-25-345-69650b99666e175f4365d62f.jpg)

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2025-12-17-21-50-24-168-694325a06438b978e7eabc63.jpg)