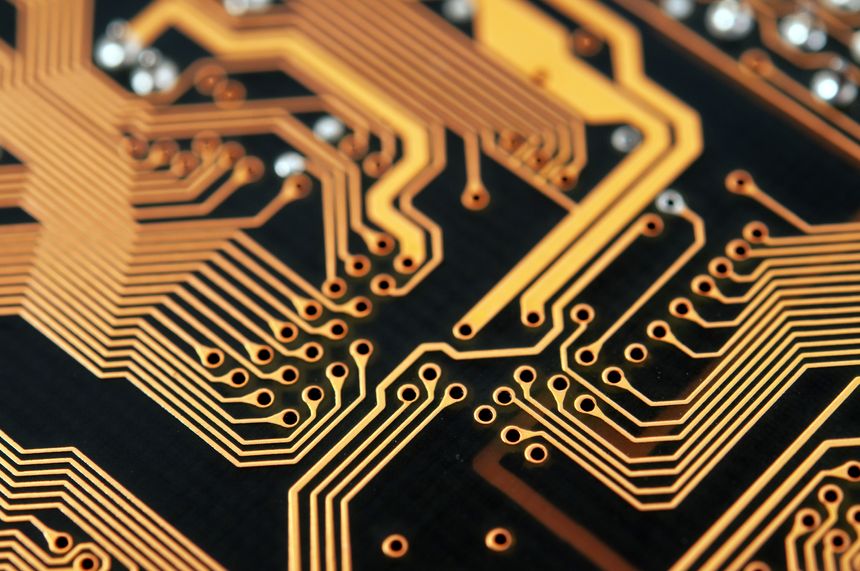

As gold becomes more expensive, manufacturers face supply chain instability and margin erosion. But the deeper issue is structural: the electronics industry still relies heavily on single‑life, hard‑to‑recycle printed circuit board assemblies (PCBAs). These designs trap valuable materials in devices that are overwhelmingly discarded, rather than recovered.

Up to 7% of the world’s gold may already be buried in e‑waste, meaning discarded electronics now hold vastly more gold per tonne than natural ore deposits — in some cases 100 times more.

This is not just wasteful. It’s a strategic blind spot. A world chasing advanced electronics cannot afford to keep burying the critical materials that make them possible.

The Opportunity: Circular Electronics as a Strategic Imperative

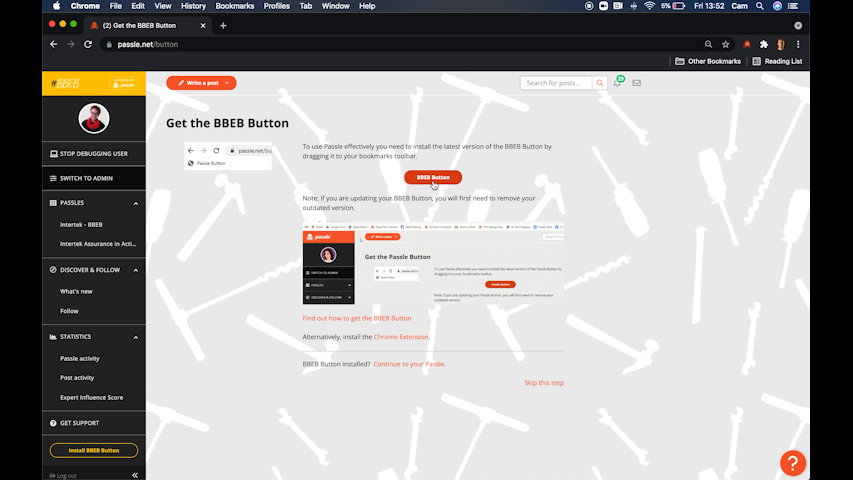

The Manufacturer highlights modular electronics as a key solution — designs where components can be easily disassembled, repaired, reused, and recycled, enabling manufacturers to recover their own gold supply rather than repeatedly sourcing virgin material.

This approach is more than an environmental initiative:

- It stabilizes material supply, insulating manufacturers from price shocks.

- It creates new revenue streams via recovered materials and component resale.

- It reduces dependence on geopolitically sensitive mining operations.

- It unlocks a more sustainable growth path for industries like consumer tech, medical devices, and renewable-energy hardware.

Circularity is not an idealistic future — it is a competitive strategy that can be implemented now.

Build Electronics for Regeneration, Not Disposal

Build Back Ever Better calls for systems that become stronger through disruption, not weaker. The gold crisis is a perfect test of that philosophy.

1. Design Out Fragility

Traditional PCBAs embed gold deep within multi‑layered structures, making recovery nearly impossible.

2. Transform Waste Into a Strategic Resource

If 7% of global gold is already in e‑waste, then the world is sitting on a massive above‑ground gold reserve.

3. Build Industrial Systems That Regenerate

Circular electronics create regenerative material loops, reducing extraction pressure on finite resources such as gold, rare earth elements, aluminium, copper, and steel — all flagged by In2tec as increasingly constrained.

Why the Electronics Industry Must Act Now

Gold’s price volatility will not be a one‑time event.

As AI, renewable energy, and advanced manufacturing accelerate, demand for high‑reliability electronics will soar — and so will pressure on material supply chains.

The Manufacturer’s analysis makes it clear: gold is too critical, too valuable, and too limited to continue discarding at scale.

High Gold Prices Aren’t the Problem — They’re the Signal

This moment is a wake‑up call, not a setback.

Record gold prices are exposing the fragility of linear electronics manufacturing and highlighting the immense value trapped in our waste streams.

For those committed to Building Back Ever Better, the mandate is clear:

Redesign electronics for circularity.

Recover what we once discarded.

Transform scarcity into security.

And build an industry that gets stronger — ever better — with each cycle.

The tech industry can counter soaring gold prices by investing in sustainable electronics that allow the easy recycling and reuse of the metal,

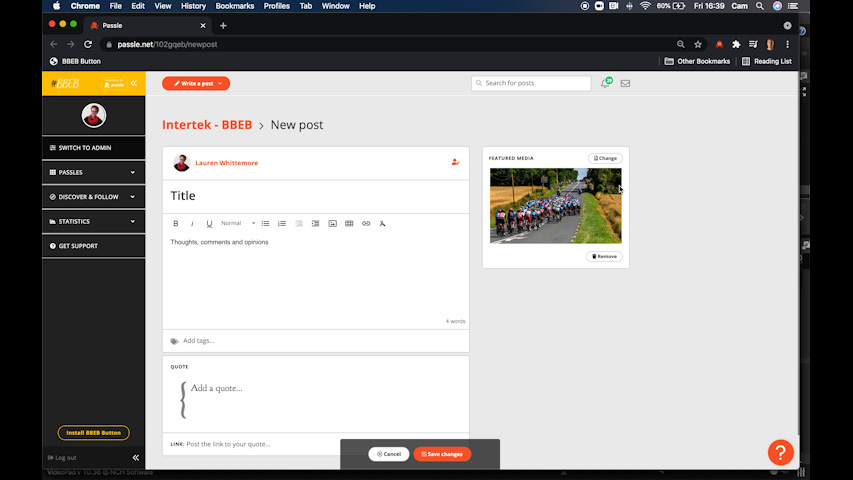

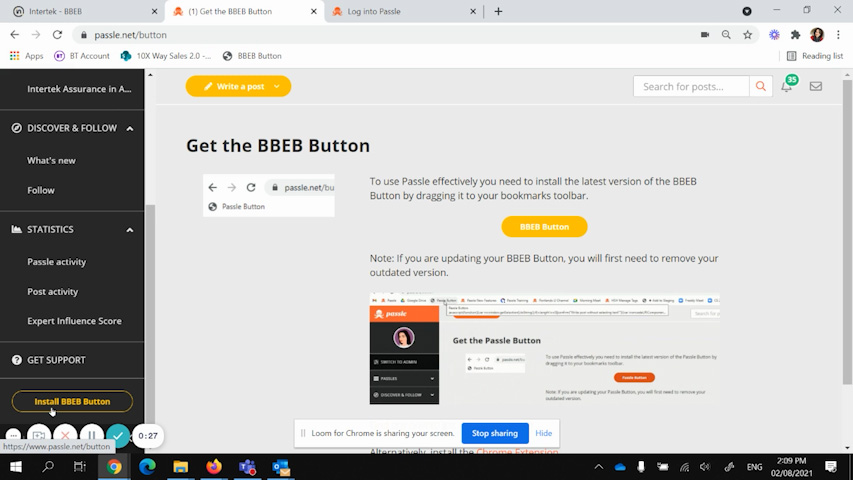

unknownx500

unknownx500

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2026-02-09-20-02-11-944-698a3d43120a9705b5de07ff.jpg)

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2026-01-12-14-56-25-345-69650b99666e175f4365d62f.jpg)