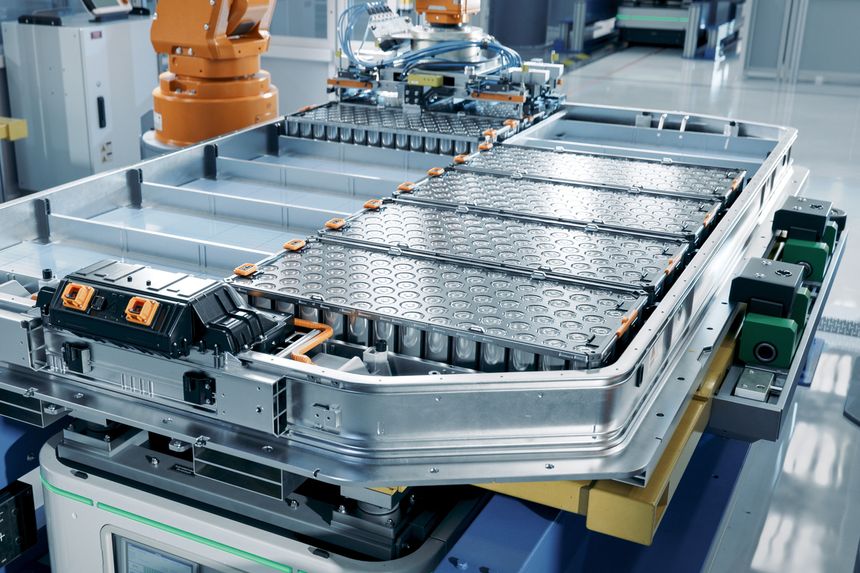

The UK’s industrial future is at an inflection point. A cross‑party UK Gigafactory Commission, supported by the Faraday Institution, warns that the next 12–18 months will determine whether Britain secures large‑scale battery manufacturing, protects over 200,000 automotive‑linked jobs, and remains competitive in the global race for EVs—or cedes ground to rivals in Europe, the US, and Asia.

Build Back Ever Better (BBEB) means rebuilding with intention: transforming shocks into structural strength, converting policy into productive capacity, and aligning energy, supply chains, and skills for long‑term advantage. The Commission’s plan offers a practical pathway to do exactly that.

Why Gigafactories Are BBEB Infrastructure

Gigafactories are more than individual projects; they are strategic national infrastructure that determine where future EV platforms are allocated, which supply chains take root, and where advanced manufacturing talent clusters. Nations that co‑locate EV assembly, cell manufacturing, and active materials will capture the next generation of automotive value creation.

Global competitors are moving fast with incentives, accelerated planning, and energy‑cost relief to anchor private investment. Without coordinated action, the UK risks declining exports and offshoring of production capacity, precisely the outcomes BBEB seeks to avert by rebuilding smarter, stronger, and more self‑reliant.

The Commission’s Three‑Pillar Plan

1) Proactive, Accountable Leadership

The Commission calls for a shift from “open for business” messaging to mission‑led, interventionist leadership, including a Cabinet‑level minister personally accountable for landing: (a) a new EV manufacturing centre, (b) a gigafactory, and (c) a domestic active‑materials supply chain. This tightens ownership and compresses time‑to‑decision—core BBEB tenets.

2) Anchor Demand and Build the Whole System

The plan prioritises securing a major global OEM as the demand anchor, then pairing it with a cell manufacturer (gigafactory operator) and active material producers to close critical gaps in cathode active materials (CAM) and anode active materials (AAM). An investable supply chain needs local CAM capacity and investor‑ready sites with power, planning, and grid access resolved up‑front.

3) Targeted Policy & Regulatory Reform

The Commission targets four friction points that routinely derail projects: high energy costs, lengthy planning cycles, slow grid connections, and site readiness. Addressing these in a coordinated package is essential to restore investor confidence and ensure UK sites compete with global alternatives on speed and certainty, not just incentives.

Why This Is the Moment to Build Back Ever Better

- Economic Security: Co‑locating EV and batteries protects high‑value manufacturing and stabilises export earnings.

- Energy Resilience: Industrial demand that is efficient, electrified, and closer to renewables de‑risks costs and enhances grid planning.

- Regional Renewal: Gigafactories catalyse clusters (R&D, tooling, logistics, training) spreading benefits across supply chains and communities.

- Net‑Zero Alignment: Domestic cells and materials shorten supply lines and cut lifecycle emissions, where climate ambition meets industrial strategy.

BBEB is not about “rebuilding what was”; it is about rebuilding what’s next; with redundancy where it matters, agility where it pays, and transparency that keeps delivery on track.

The commission stresses that competitiveness also depends on a policy environment that gives manufacturers confidence to invest. It calls for reducing industrial energy costs by increasing and broadening Energy Intensive Industries relief; recalibrating the Zero Emission Vehicle (ZEV) mandate to maintain ambition while avoiding penalties that constrain growth; and negotiating a phased approach to the 2027 Rules of Origin deadline given limited UK and EU active cathode and anode materials manufacturing capacity.

https://www.pesmedia.com/crossparty-commission-sets-plan-to-secure-uk-gigafactories

unknownx500

unknownx500

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2026-01-12-14-56-25-345-69650b99666e175f4365d62f.jpg)

/Passle/5e4a7839abdfeb03584d01f6/SearchServiceImages/2025-12-17-21-50-24-168-694325a06438b978e7eabc63.jpg)